TH1 32 | Project GTR Festival 2025

TH1 32 | Project GTR Festival 2025

Build Gallery

From Street Spec to Show-Stopper: Behind the Build of TH1 Blue R32 GTR

It all kicks off with a clean but completely standard R32 GTR rolling into the Concept Garage HQ. Before it can earn a spot at the GTR Festival, it’s stripped down to a bare shell, engine out, interior gutted, windows removed, and all trim carefully taken off. This stage is about exposing everything we’re working with and setting the stage for a full transformation. It’s more than just a respray, this is a complete rebuild from the ground up.

With the shell bare, it’s time to get serious. Benny meticulously inspects every square inch of the body, circling damaged or imperfect areas with a marker. From dings and dents to stress cracks, nothing goes unnoticed. Each flaw is then expertly repaired using proper metalwork techniques. No shortcuts here. Every panel gets the attention it deserves to make sure this GTR comes back straighter and cleaner than ever.

Next, Benny gets hands-on with one of the most oddly satisfying jobs in the process: badge removal. Armed with a caramel wheel, he gently lifts off decades-old emblems without damaging the factory paint underneath. There’s something therapeutic about watching it all come clean. Just one of those little moments that keeps the process fun.

Benny showing us the most common bonnet damage spots…

Now comes the part where Benny flexes the OCD. Every door, guard, bonnet, and boot lid is adjusted to get those gaps tighter and more symmetrical than the factory ever managed. It’s one of those details you don’t notice right away, but it’s what separates a clean build from a proper showpiece. The shut lines on this GTR will be on another level.

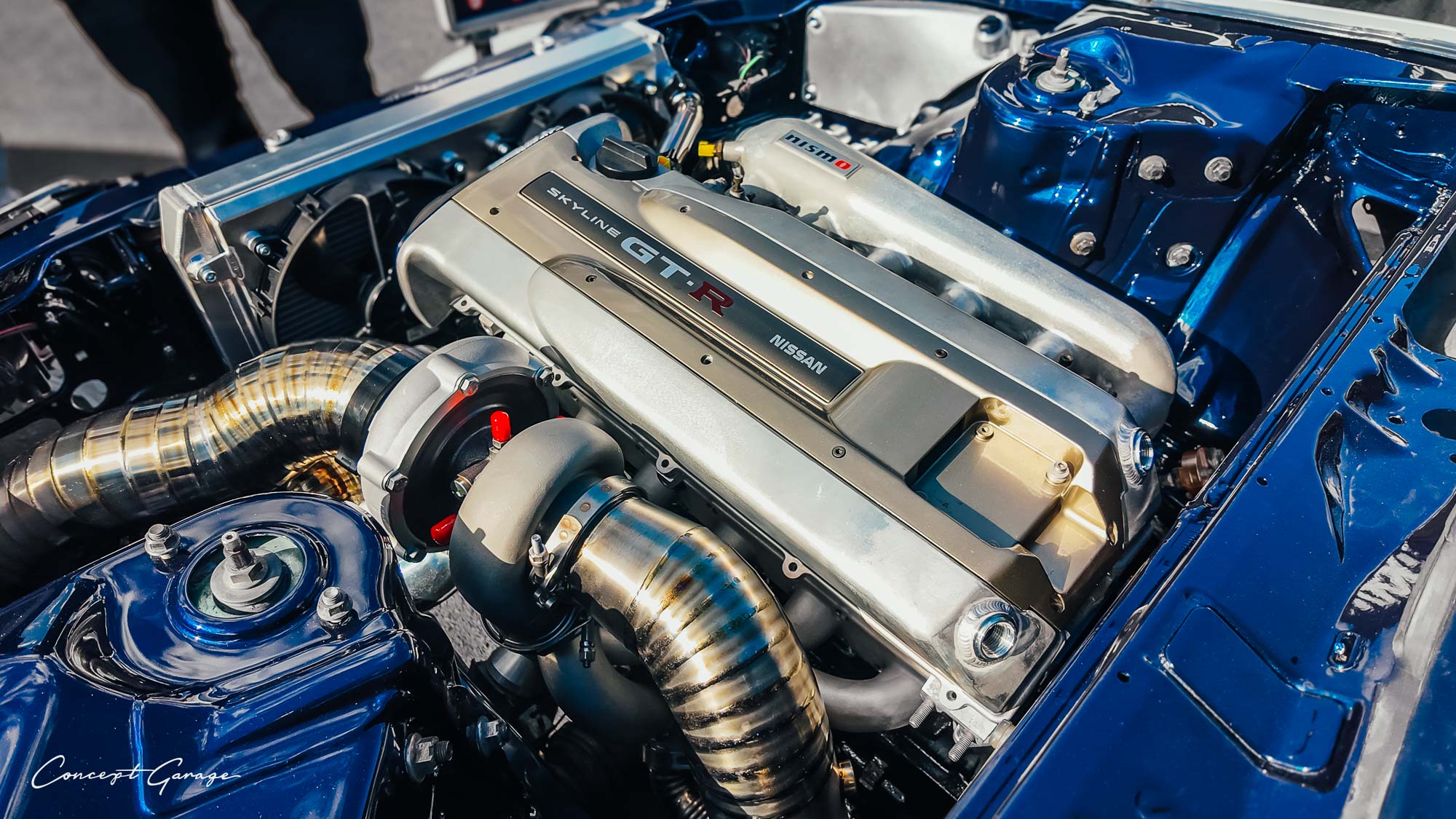

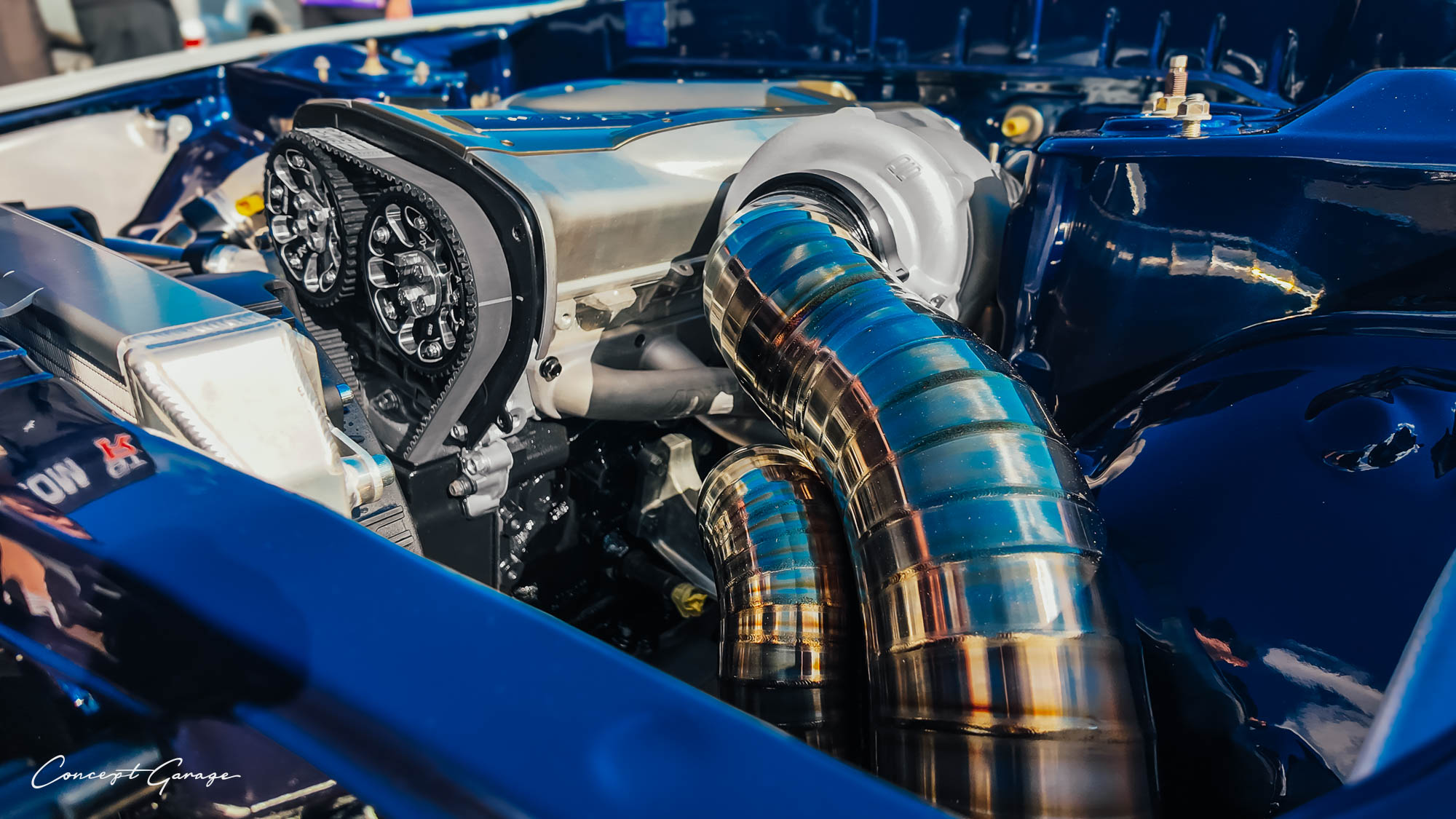

Under the bonnet, the transformation is just as serious. The engine bay has been completely shaved and smoothed. All unneeded holes and brackets removed, welded, and reshaped. This space is being prepped to house a brand new, ProForm forged RB26 package. It’s not just about performance, it’s about presentation too. Clean, modern, and unique.

Now that all the gaps are perfect, Benny gets the shell prepped for the paint booth. Every surface is double-checked, cleaned down, and masked up with precision, ready for its first full coat of primer. It’s the kind of preparation that makes the later paint finish truly shine.

Once the shell and parts are prepped, everything heads into our paint booth for a full coat of primer. This not only seals and protects the work, but also gives us a clean canvas for the next stage of paint and finish. We’ve captured the entire process in a raw, satisfying POV ASMR-style video, keep an eye on our socials, you’ll want to see this one.

Once the primer had cured and the shell was locked in, we took the opportunity to 3D scan the entire interior. This step was crucial for what came next: designing a perfectly fitted chromoly roll cage. With accurate digital data, we could ensure the cage would follow every curve and contour of the interior. Maximum strength, minimum guesswork.

With the cage fabrication now complete, the focus shifted back to the engine bay. While the GTR would be shown in the “In the Build” category at GTR Festival, we weren’t going to half-send anything. So we decided to give the bay a fresh lick of the rich, deep custom Blue we developed in-house. Something bold and brilliant to hint at what’s coming next.

A few more hours of careful hand-sanding and the bay was booth-ready. It’s amazing how much finesse goes into this part. No corners, no rough patches, just glassy-smooth surfaces and the kind of masking job that would make a surgeon proud.

Boom! Deep, deep Blue.

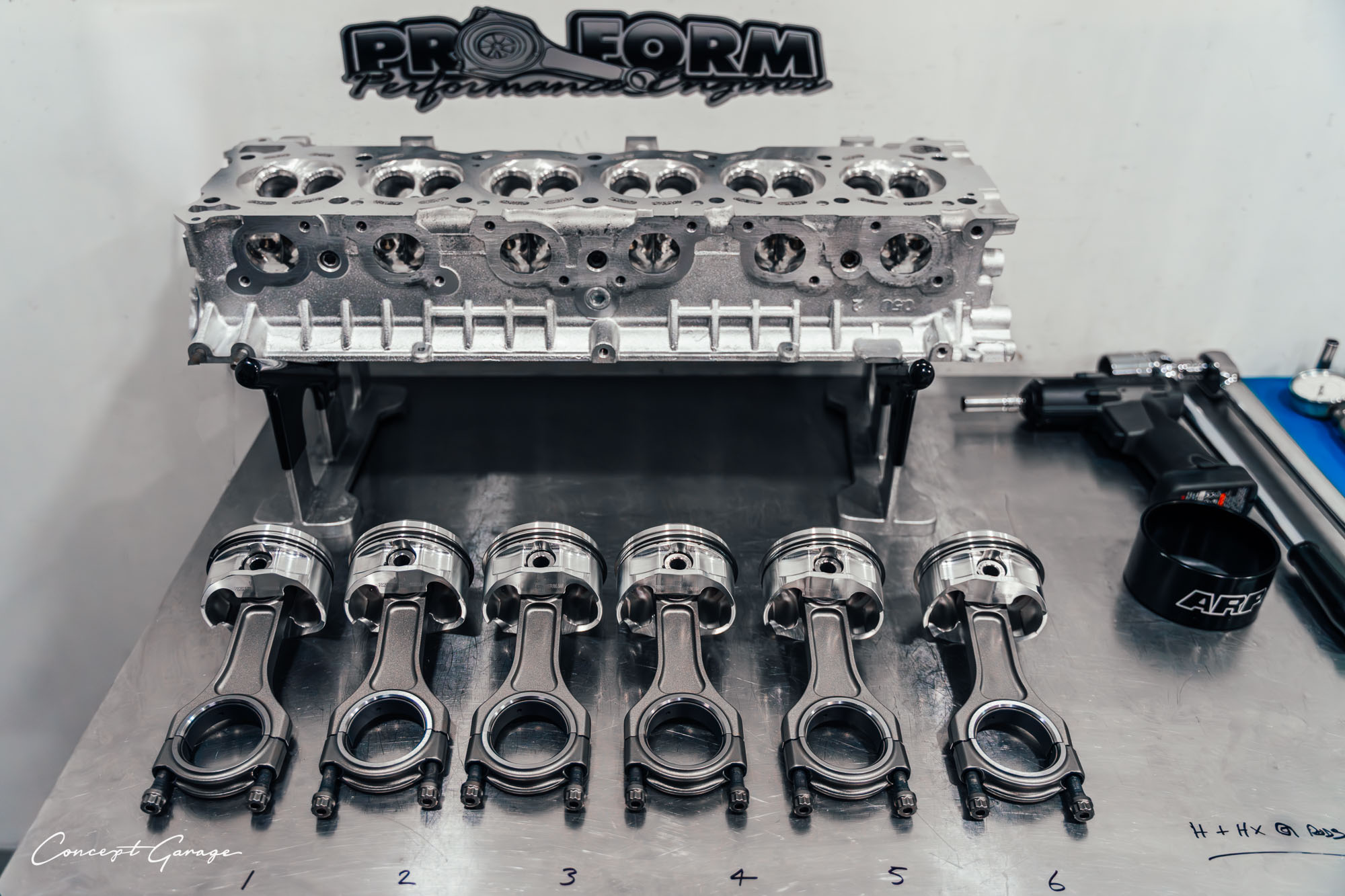

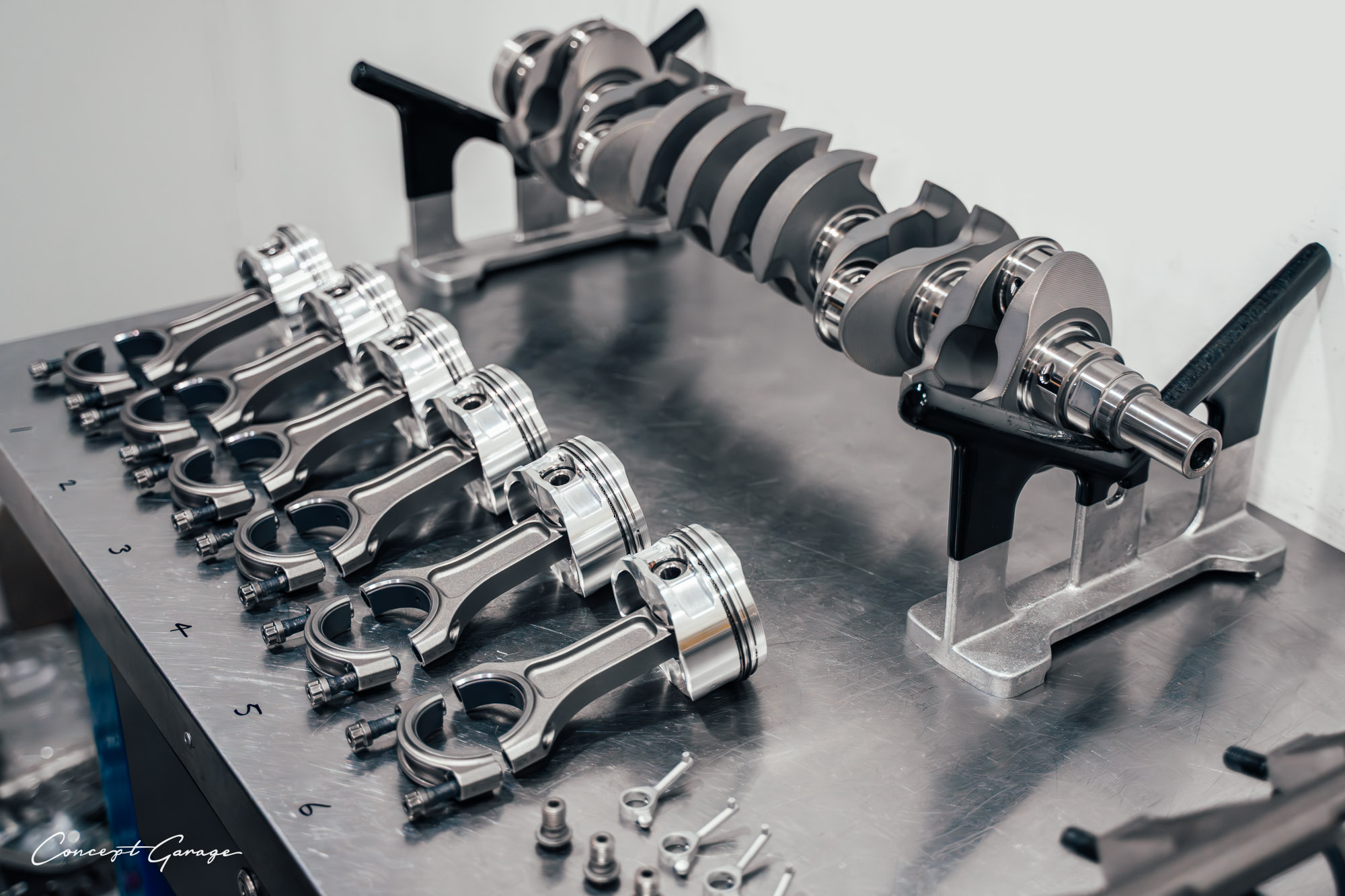

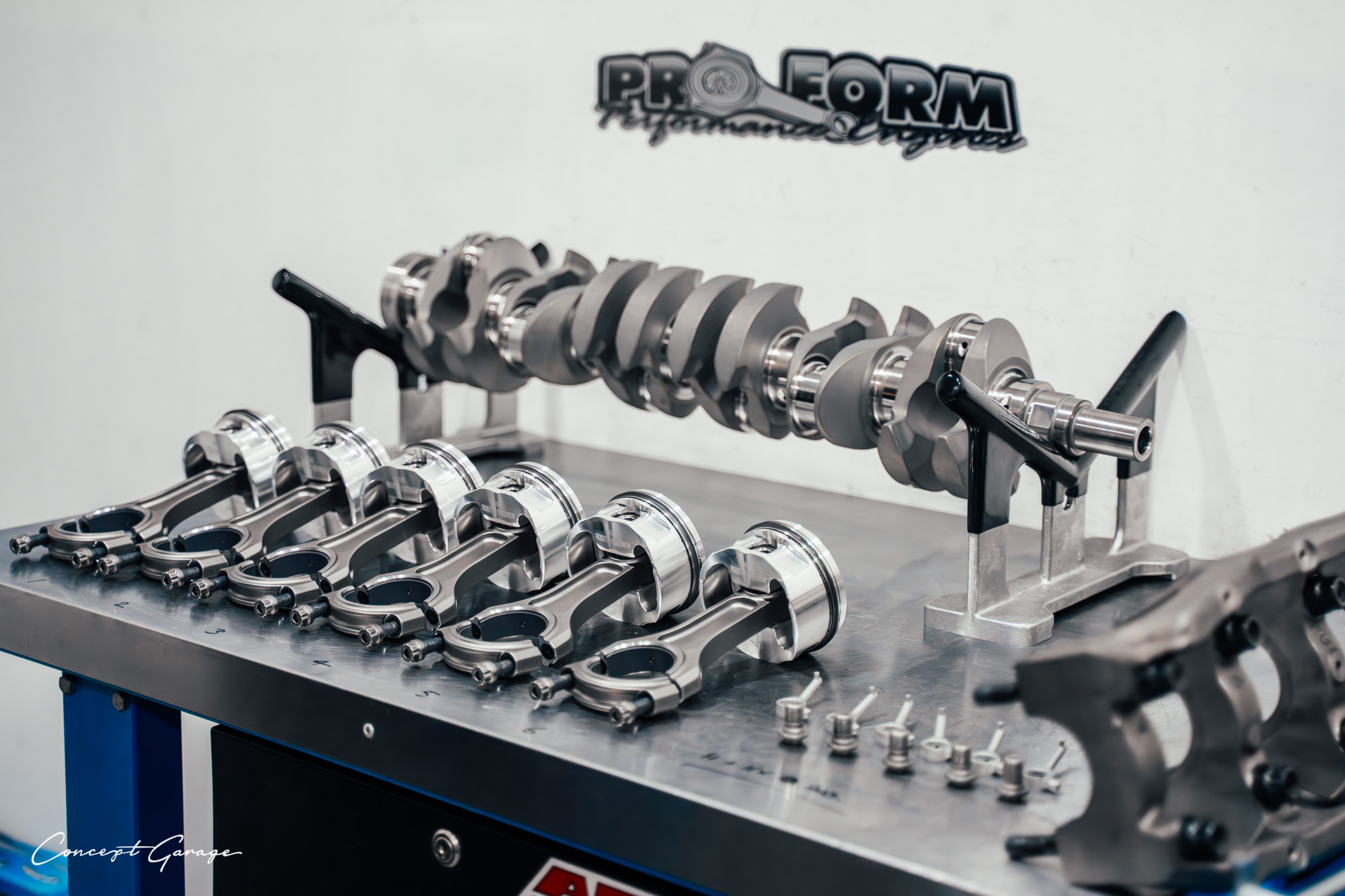

While the boys suited up and headed into the booth to spray the bay, we paid a visit to our good mate Gabby at Proform. Over in the engine room, the magic was happening, the brand new RB28 Nitto engine build was underway. And yes, we’ve got all the pics and footage. Engine nerds, this one’s for you.

We’re not sorry for the engine porn. Every bolt, every bearing, every precisely torqued part, it’s all a joy to witness. Gabby doesn’t just assemble engines, he crafts them. Watching this RB come together was a masterclass.

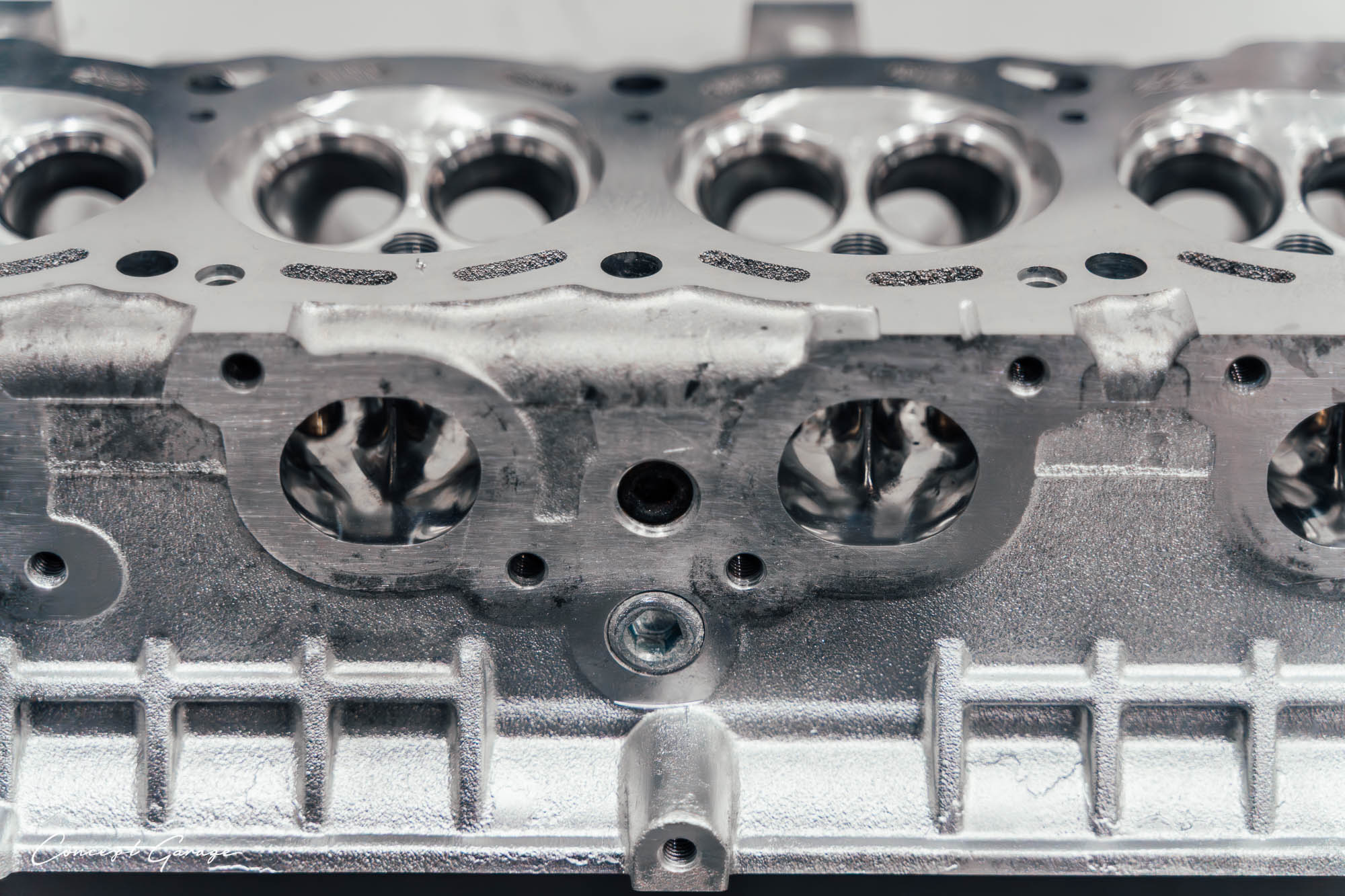

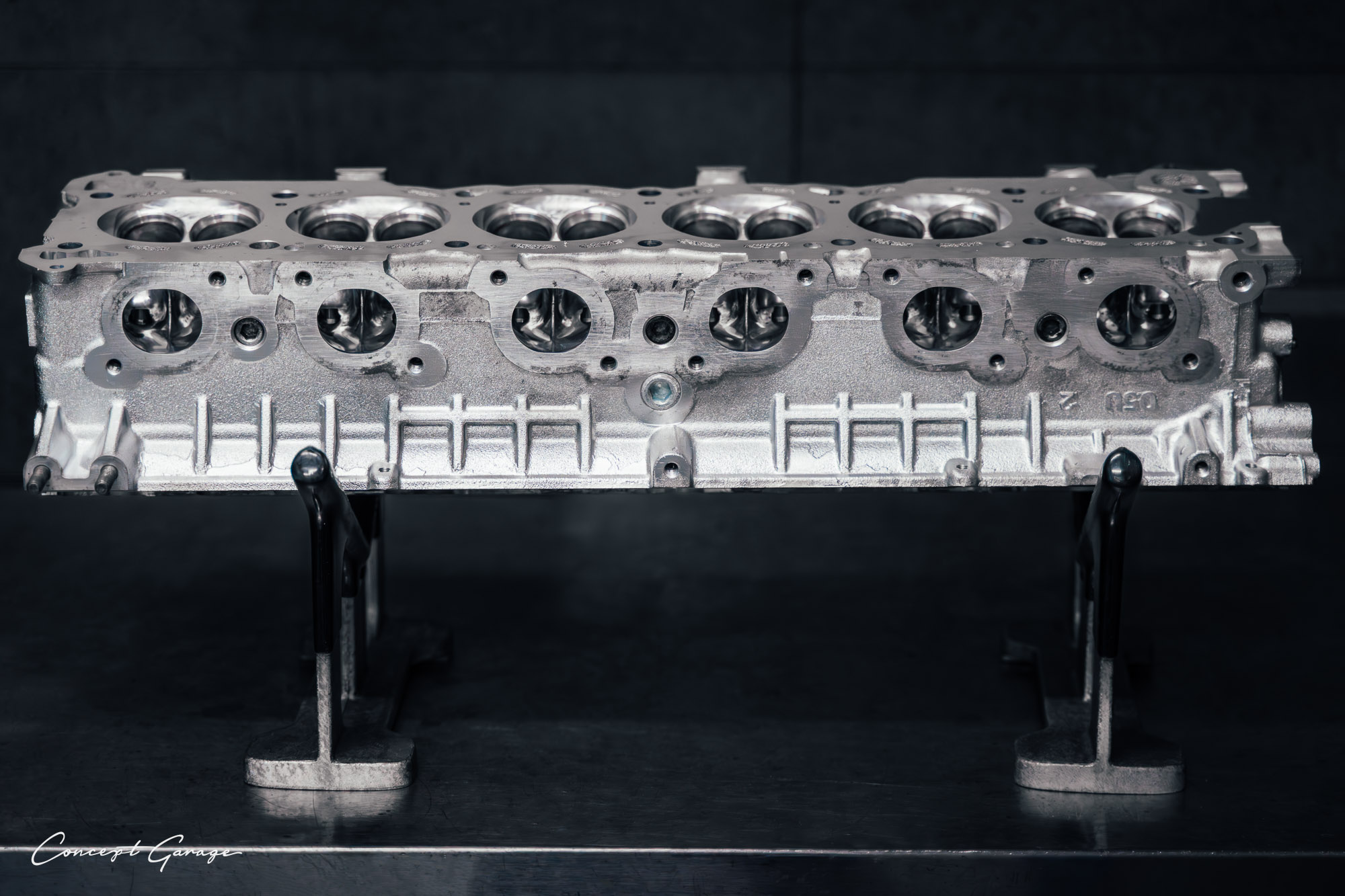

One of Gabby’s true specialties is cylinder head work. His porting and polishing game is elite. Smooth, high-flow channels that don’t just look good, but deliver serious performance. It’s these finer details that turn a tough build into a truly exceptional one.

And yeah… we couldn’t help ourselves. One more gallery of shots with the head on the stand. Sharp lighting, glinting metal, that unmistakable Proform touch. These photos are going straight into the “screensaver-worthy” folder.

And now here we are, GTR Festival is tomorrow! What an epic effort from the whole team to bring not one, but two project cars to life in time for the big reveal. A huge thanks goes out to the crew at Jammas Auto Sports and Aaron from Overtime Fabrication for coming through under serious pressure. Gabby had the engine built, the Jammas boys had it installed, and Adrian knocked out the full titanium intake and exhaust setup in just two long days. From the shell to the show floor, every late night and detail check was worth it. We’ll be loading both cars onto the tow trucks at 11PM, headed straight for Sydney Dragway. Let the Festival begin, stay tuned for content from the show!

A few late photos post-GTR Festival. We just couldn’t resist sharing these late additions. Massive thanks again to everyone who played a part, especially our Concept Garage crew who went above and beyond in the final stretch. The last two months were a blur of late nights, long days, and all-out hustle.

Stay tuned as we’ve got loads of video content on the way, including full build breakdowns for both GTRs we brought to the festival this year. You’re going to want to see how it all came together.